Traceback your T-shirt

and explore your

impact on people

& the environment

Creating a

FAIR ECONOMY

15-20%

higher raw cotton price for the benefit of the farmer

Creating a

FAIR SOCIETY

40%

of NatureTex employees are females. the aim is 50% to promote gender equality.

Life Long Learning &

WELLBEING

10%

of the working time in NatureTex is dedicated to art and self-development activities; to promote wellbeing and

happiness at work.

Protecting the

ENVIRONMENT

30.5%

water was saved by using biodynamic, regenerative methods compared to conventional cotton cultivation.

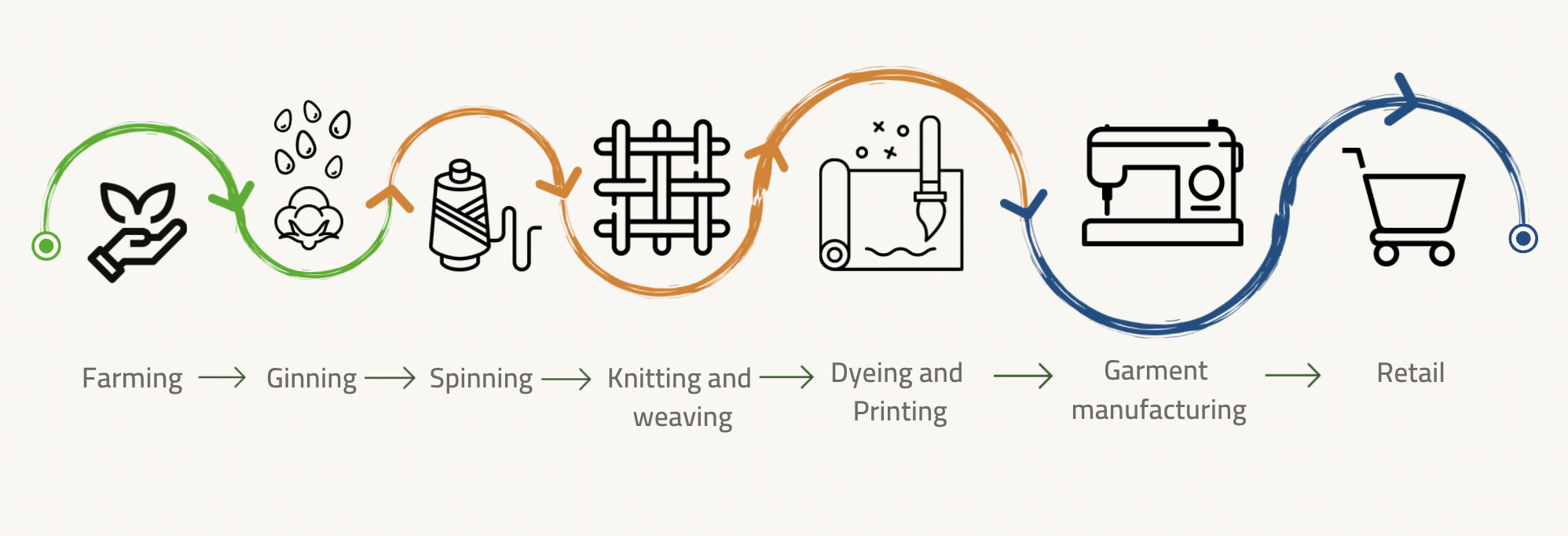

Value Chain of the Sheet

Check out the process this sheet goes through to get to you!

Farming

The T-shirts start as cotton flowers, with the variety Giza 95. This specific kind of cotton is special for Egypt and is cultivated in a city called Fayoum located southwest of Cairo. This high-quality long-staple cotton was cultivated using a holistic and regenerative approach called biodynamic agriculture.

During the cultivation of the cotton, no synthetic pesticides or fertilizers were used. This way, the farmer preserves the biodiversity of the soil and surrounding and protects the water and air from pollution, as well as his own health.

EoL certified cotton is sold at a higher price to ensure that the farmers’ economic situation improves and they become more self-sufficient and support the development of their community.

Economy of Love provides their farmers consultancy and information about regenerative/biodynamic agriculture to develop their skills and knowledge about useful techniques.

Meet The Farmers

get to the source of production

Ashry Sakaran

Farmer in Fayoum, Egypt

Ashry Sakaran grows Demeter-certified biodynamic cotton, along with other crops, in Fayoum, southwest of Cairo. He started to believe in the importance of biodynamic agriculture after noticing a difference in health-related matters since his conversion from conventional methods.

Ahmed Tawfik

Farmer in Fayoum, Egypt

Ahmed Tawfik has his own Demeter-certified biodynamic farmland in Fayoum, where he grows cotton, Giza 95. His father has been working with SEKEM for 30 years. He grew up not knowing any other agricultural methods than the biodynamic methods. He seeks to further develop, biodynamic agriculture in his surrounding area.

Gomaa Hassan

Farmer in Fayoum, Egypt

Gomaa Hassan has his own Demeter-certified biodynamic farmland in Fayoum, where he grows cotton Giza 95, along with other crops. He’s been working with SEKEM for 24 years. Gomaa believes in the importance of biodynamic farming, as it doubles the production and protects his family’s health as well as his own.

Mahmoud Rabiea

Farmer in Fayoum, Egypt

Mahmoud Rabiea has his own Demeter-certified biodynamic farmland in Fayoum, southwest of Cairo. Along with other crops, he grows Cotton Giza 95, where the weather in Fayoum is the most suitable for this specific Giza.

Processing

(Ginning and Spinning)

Following the principle of circular farm organism, the cotton seeds are returned to the farm, where the cotton was initially cultivated, to be reused; for the upcoming season. Seeds that are not reused on the farm are used for cottonseed oil or animal fodder.

The spinning of the cotton is outsourced to a company located in Sadat city, in the northwest of Cairo.

In addition to the environmental criteria, fair treatment and well-being in the supplying companies are guaranteed through the Economy of Love Code of Conduct and the social criteria of the GOTS certification.

Processing

(Knitting, Dyeing and Finishing)

Moving on to the next step, the spun yarn goes through a process called knitting, which gives us both; the single jersey fabric and the rib fabric for the neckline. After which it goes on to the dyeing and finishing processes.

Dyes are often done through harmful chemicals that are bad for the skin and the environment. The Demeter and GOTS certifications ensure that the inputs being used in the processes of dying and finishing are Eco-friendly, biodegradable, and non-hazardous, with no toxins.

The dyeing facility located near Cairo abides by the most stringent legal requirements for the treatment of wastewater before its disposal.

Factory workers work in safe conditions, methods that may endanger the health and safety of the workers are prohibited.

Sewing & Finishing

Now the fabric arrives in NatureTex. It gets tested to ensure the quality is according to the standards. When all is correct, the fabric is cut and sewn together then ironed, and the T-shirts are ready to go.

To ensure that nothing goes to waste, NatureTex sells the waste fabric from the cutting process to be recycled, and they reuse the organic cotton fiber waste from the spinning process to use as doll stuffing. As for the leftover stock fabric, it is turned into carpets.

Safety precautions are taken while operating machines in the factory to ensure the safety of the workers, in addition to the occupational medical assistance they receive.

NatureTex factory has implemented the Core Program which enables all factory employees to engage in courses of art, acting, music, origami, and many more to promote happiness and balance at work.

Packaging Material

The T-shirts are now packaged individually in poly bags. After which, they are packed together in carton boxes: ready to be shipped and distributed to the retailers. Packaging materials have a huge impact on the products’ lifetime impact, and cannot be neglected.

The poly bags the t-shirts are packed in are made from recyclable material, while the carton boxes are biodegradable.

The manufacturing and transportation of packaging materials such as carton boxes and poly bags are accounted for in the calculation of the product’s emissions. The company is actively working on reducing them.

As part of SEKEM holding, NatureTex is involved in tree planting an was therefore able to sequester more CO2 than its emissions and thus continued to be carbon positive in 2020 and 2021.

Distribution

The T-shirts are now ready for distribution. They’re transported by trucks to different local customers or ports to be shipped to international clients.

The supply chains transportation emissions are monitored by the sustainability department of the SEKEM Holding. The data includes all the transportation required starting from the farm till it reaches the local/international retailers’ shelves.

NatureTex mainly uses sea freight for international shipments; to reduce emissions and to have the least possible overall impact on the environment.

As part of SEKEM holding, NatureTex fully offsets its carbon emissions for transportation.

Meet The Employees

The people who processed, packaged and distributed your product

Vivian

Merchandiser in NatureTex

Vivan has been working in the merchandising department in NatureTex for 8 years. She’s very passionate about the field and hopes to continue doing it for as long as she can.

Jing

Quality and Production Engineer

Jing has been a quality supervisor at NatureTex for 14 years. She came to Egypt from the Philippines and stayed as she grew attached to her team, who became like family to her.

Yassmin

Packaging and Labeling Assistant

Yassmin lives in Galvina with her family. She was a student at SEKEM vocational schools and has been a NatureTex employee for 13 years.

Waleed

Textile Printing Engineer

Waleed is from Banha, he’s in charge of the silkscreen prints and colors in NatureTex printing house. He’s been a SEKEM employee for 23 years. He’s an avid worker who values his job.

What is the True Price?

Are there hidden costs that the price doesn't reflect?

True Price Comparision

Sustainably and ethically produced products add value to society and the environment. However, when comparing prices, we don’t take into account the long-term and externalized impact of the products we purchase.

For example, we know that this biodynamic cotton emits greenhouse gases – such as Co2-eq, costing society up to 0.042 USD/kg, and about 0.37 tonnes Co2-eq per tonne of cotton. However, compared to conventional methods, this biodynamic cotton cultivation produces 75% less Co2-eq.

We encourage you to compare products based on their true price; the price that reflects the hidden costs that we and future generations eventually pay for.

This cultivation of cotton costs up to 0.042 USD/Kilo, by emitting carbon into the atmosphere

What is the Water Footprint on the Farm?

By looking at a product’s water footprint, you can assess the amount of water used throughout the production process, from the farm until it becomes fabric. That way you can make an informed decision based on the product’s impact on water resources.

3050 liters per kg were used to cultivate the raw cotton.

Around 30.5% less water compared to conventional cultivation methods in the same region.

Since some countries have fewer water resources than others, it’s not only important to know how much, but also, where it comes from to appropriately measure your impact on those resources.

The Water Footprint of cultivating the

cotton for this T-shirt is

457 liters

Examples of Hidden Costs

Costs that are not reflected on the price tag, but are eventually paid by society

WATER

REPROCESSING COST

Society is paying taxes to clean water sources from agriculture’s chemical fertilizers, pesticides and herbicides, as well as the irresponsible disposal of wastewater from factories, in order to make it usable/drinkable water.

HEALTH COSTS

Society has to bear the long-term cost caused by disruptive agriculture e.g. soil erosion, desertification, loss of biodiversity.

ENVIRONMENTAL

DAMAGE

Society has to bear the long-term cost caused by disruptive agriculture e.g. soil erosion, desertification, loss of biodiversity.

Locations

Check out the locations of all the farms, companies who were involved in making this product!

discover the origin of your product

Eraky Farm

Add an optional description to your map pin economyoflove

Mashour Farm

Add an optional description to your map pin economyoflove

Abo Hamad

Add an optional description to your map pin economyoflove

Mahmoud Rabie farm

Add an optional description to your map pin economyoflove

We hope this information helped you Choose Your Impact!

And make mindful purchasing decisions that leave a positive impact on people and the environment

Interested to know more about the companies above? Click here to download the SEKEM Sustainability Report